- Proximity Transducer System

Eddy current transducer can either conduct dynamic measurement or static measurement. It is mainly used for vibration and displacement measurement and key-phase and rotating speed measurement for oil-film bearing machinery. The eddy current system can conduct continuous monitoring for rotating shaft’s rotating state or rotor’s mechanical problems of, e.g. imbalance, de-centering, bearing wear or shaft cracks, etc., to provide critical information for early determination. The 3015/3018/3011/3025 series transducers apply the advanced design concept and are characterized by wide measurement range, high sensitivity and resolution, quick response speed, strong anti-interference, free of media influence, e.g. grease, etc., simple structure, etc. It meets the API (API670) standard. In addition, the eddy current probe, extended cable and proximitor have reliable interchangeability; the 5m or 9m monitoring system composed of the transducer, proximitor and extended cable is widely applied in the vibration state monitoring and fault diagnosis of large rotary machinery

For radial vibration measurements, mount the probe perpendicular to the shaft with the probe tip approximately 0.040” (1.00 mm) from the shaft surface. Provide the probe tip with sufficient clearance from surrounding metal to prevent an erroneous output. As a minimum,the clearance diameter should be 0.75” (19 mm) for the full length of the probe tip.You can set the probe gap “electrically” to the center of its measurement range by observing the DC output voltage at the BNC connector on the 3082 or the terminal block connection on the 3082with an isolated meter. Adjust the probe gap to obtain -10 VDC, which corresponds to a gap of approximately 0.040” (1.00 mm). The preferred static gap is 0.032”. This gap corresponds to a voltage of -8.0±0.5VDC. For position (thrust) measurements, mount the probe with the probe axis parallel to the shaft and with the probe tip approximately 0.050” (1.25 mm) from the end of the shaft.This gap corresponds to a voltage of -10.0±.5VDC.To prevent cross-feed between two probes mounted in the same vicinity, maintain a minimum 1.0” (25 mm) spacing between the probe tips.

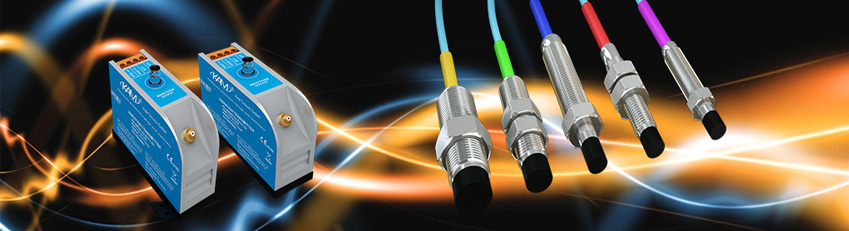

Probe/Coaxial Cable

The3025/ 3011/3018/3015 series transducer probes apply the brand new design to let this probe with long service life, more stable and more reliable output. The newly specially made co-axial cable applies sealed and anti-pull design to prevent the leakage of oil or other liquid to the outside from the inside of cable and can bear 300N tensile force. The gold plated copper connect enable the probe to connect cable in a firmer way and can ensure functions and stability of the transmission system and stable operation in severe environment.

Proximity

The 3082/3092 series proximitor applies the advanced integrated circuit technology to make the system with higher precision and stability. The advanced electromagnetic interference/radio frequency interference resistance greatly enhances the equipment’s radio interference resistance. It can use both lead rail installation and panel installation. Two forms of installation base board have electric insulation and need no independent insulation board, thus reducing installation costs and complexity of installation.